Power equipment

To date, GAZMASHPROEKT performs work on capital and current repair of electrical equipment branches in Orenburg and Astrakhan.

The complex of works on repair of electrical equipment includes such operations as:

- installation and commissioning of switchboard equipment;

- overhaul and repair of backup power sources;

- capital repair of lightning protection;

- installation and commissioning of СTР (complete transformer substations);

- installation of lighting lines;

- overhaul of external and internal networks of power supply;

- maintenance of electrical equipment of ventilation systems;

- technical maintenance of fire security

Currently GAZMASHPROEKT shall maintain construction and Assembly works, monitors the deadlines and quality of work, develops schedules of manufacture of works, funding and regulates the movement of labor, ensures the supply of all necessary construction materials and equipment, strictly observe the safety conditions of construction works, health and the environment. Constant interaction with reliable partners allows us to perform work at different levels of complexity.

The aim of the work of specialists GAZMASHPROEKT is a high-quality performance of assigned tasks to ensure safe and durable operation of the equipment.

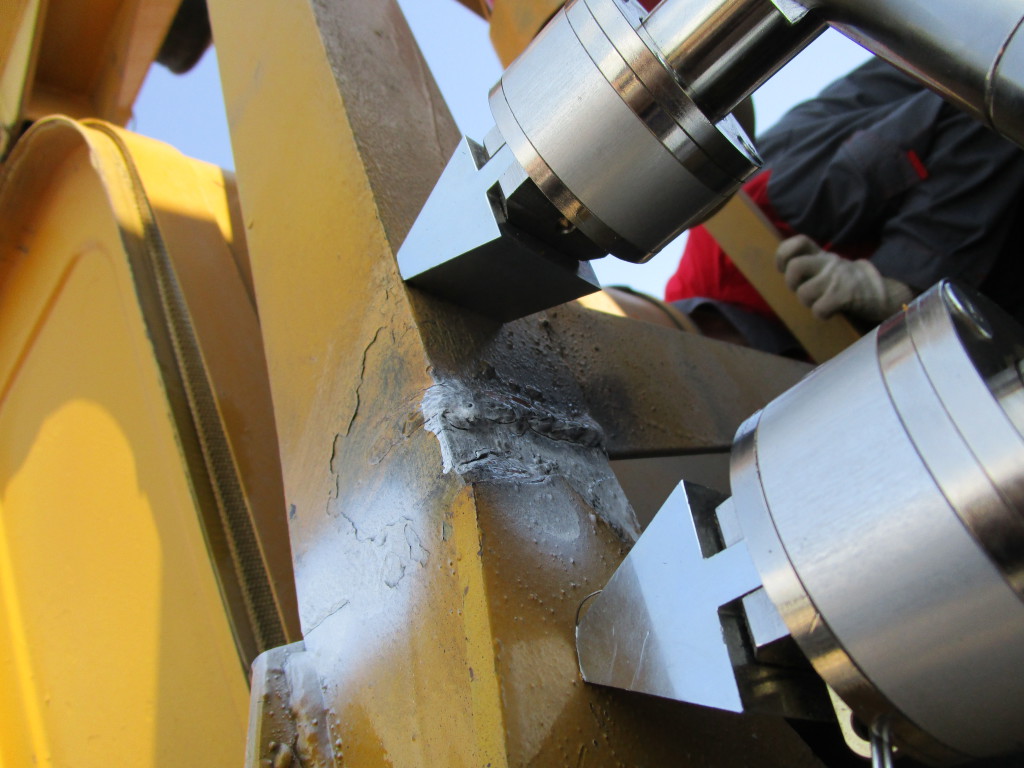

Repair of anticorrosion coatings

GAZMASHPROEKT performs work for corrosion protection of aboveground steel structures, process equipment and building structures with the use of water-jet and blasting methods of surface preparation (degree of surface cleaning to Sa3) with the use of different abrasive materials, chemical washes and rust converters, with a wide range of systems for surface protection, in any weather and climatic conditions.

The aim of the work of specialists GAZMASHPROEKT is a high-quality performance of assigned tasks to ensure safe and durable operation of the equipment.

Metallization

One of directions of activity of the company is the development, study and application of thermal spray coatings for structures made of different materials, in different industries.

Types of coatings: corrosion resistant, wear-resistant, anti-friction, thermal barrier, thermal control, electrically conductive, heat-resistant, optical, decorative, electrical.

The aim of the work of specialists GAZMASHPROEKT is a high-quality performance of assigned tasks to ensure safe and durable operation of the equipment.

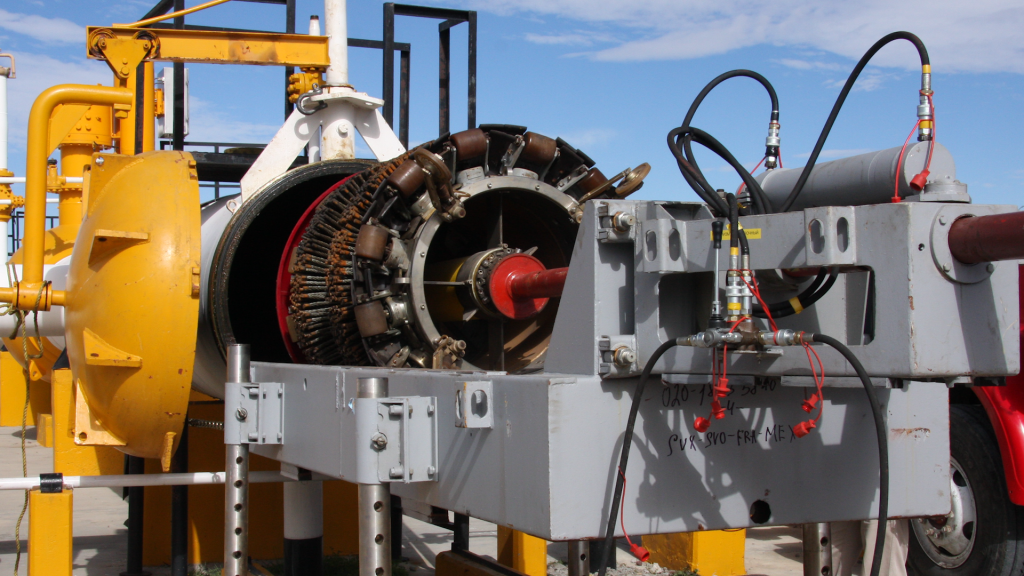

Removal of polymeric coatings from metal surfaces by induction heating

Process unit “UIN-60 / 50SP” is designed for heating of steel surfaces for flaking caused to them coatings.

Removing the old polyethylene coating on the surface of the current pipeline is made in order to further surface preparation before applying anticorrosion coating.

The operating principle of the process plant “UIN-60 / 50SP” is based on the effect of delamination of polymer coatings to steel surfaces by heating the surface layer of steel by inducing therein electric eddy currents (Foucault currents) by high-frequency alternating electromagnetic field.

Process unit “UIN-60 / 50SP” is made in a mobile version with the ability to work in tight spaces without dismantling the product in the horizontal and vertical planes.

Supersonic termoabrazivaya technology of surface preparation

This technology enables high-quality and high speed to prepare the surface for subsequent application of protective coatings and metallization.

For the best coverage interval between cleaning the surface and applying a protective coating does not exceed 30 minutes.

During cleaning and extra activation surface for improved adhesion and anticorrosive properties of the coating.

Main characteristics:

The degree of purification – Sa3

Maximum Performance -40 m2 / h

More…

Inspection of industrial safety

GAZMASHPROEKT – the expert organization, the base of which is a professionally organized staff, with extensive experience and high level qualifications in the subject area, capable of using modern software and hardware tools to perform work and provide services to ensure the safe operation of the equipment of fuel and energy complex of the Russian Federation (TEK RF). All our activities are based on licenses of Rostekhnadzor and other permits, provided the requirements of the Industrial Safety System and TEK RF.

Embedded in GAZMASHPROEKT the quality management System enables the business processes in accordance with GOST ISO 9001 – 2011.

GAZMASHPROEKT has extensive experience in the development, implementation, and diagnostics of technical devices of hazardous production facilities of the fuel and energy complex of the Russian Federation. The accuracy and quality of diagnosis (including examination of industrial safety), is provided by highly qualified NDT technicians and also experts of the industrial safety system. The current system of quality management allows you to eliminate non-production losses, errors, ensuring high technical level and profitability and the processes of diagnosing and control at all stages.

Strategic goal GAZMASHPROEKT in this direction – the formation of the Company as a leader among diagnostic organizations through the introduction of new modern scientifically sound and experimentally proven software and hardware tools, and instructional techniques of diagnosis and examination, ensure the accuracy and reliability of obtained results and calculations of the resource of technical devices and equipment for the improvement of the quality management system processes at all stages of the diagnostic service.

Non-destructive testing laboratory (NDTL)

GAZMASHPROEKT, desiring access to the processes of diagnosis highly skilled NDT technicians, carries out constant training of personnel and periodic re-evaluation using specialized computerized training systems and attracting certified training centers in the following types (methods):

- Control the stress-strain state (NDS): ultrasonic, magnetic, visual and measuring, strain gauge

- Ultrasonic (flaw detection and thickness measurements);

- Acoustic emission;

- Magnetic;

- Eddy current;

- Penetrating substances;

- Vibration diagnostics;

- Heat;

- Visual and measuring.

Personnel structure:

- 4 candidates of technical Sciences;

- 73 expert of higher qualification;

- 25 professionals NDT III (highest) qualification level;

- 223 NDT Technician level II qualification.

Infrastructure

- GAZMASHPROEKT has developed and uses specialized systems (vessels, pipelines etc.) for qualification of NDT personnel (including stand simulating different types and options NDS tubing) and testing methodology of diagnosis;

- Accredited in the system of government standards NDT laboratory is equipped with more than 423 units of specialized equipment, and SOPs;

- Fleet of cars 51 pieces; mobile lab – 5 pieces.

Ensuring the quality of the work is done by strict compliance with the requirements of the quality management system GAZMASHPROEKT involving, first, the permanent monitoring and reporting on all stages of the work, and unconditional cooperation of all departments of GAZMASHPROEKT to achieve our Client’s goals. The quality management system also provides for control of the use of the updated normative documents, and compliance with the rules and regulations of applicable regulatory documents the TEC of Russia (including Public Joint Stock Company “Gazprom”)

Non-destructive testing laboratory

Central Laboratory of nondestructive testing in the face of its head is carried out:

- Timely supply of laboratories of nondestructive testing modern means of NDT and flaw measurement, auxiliary equipment and consumable materials

- Timely provision of measurement equipment for verification and calibration (accounting and support at the object of diagnosis)

- Transfer NDT specialists, traveled to the secured object a traceable means of measurement and control

- Responsible for the timely formation of the application for purchase of materials is head of the laboratory

- In the laboratory and concentrated SO and SOPS and health validator means of flaw measurement and control

- In Central NDTL has all guidance documents to the means of measurement, and flaw measurement In collaboration with the chief metrologist registers maintained SO the SOP and the recommended STO, RD, the OST for the respective types of NDT, is documenting the issuance of the object of diagnosis and acceptance after the work of all technical means used in the process of diagnosing.

Electrolaboratory

The commissioning works, preventive testing and measurements of electric equipment and units with voltage up to 10 kV:

- Checking the status of elements of grounding devices of electric installations;

- Check circuit between earthing and grounding elements of electrical equipment.

- Measuring soil resistivity and resistance of grounding devices of all types, the insulation resistance of cables, windings of electric motors, apparatus, secondary circuits, electric wiring and electrical equipment with voltage up to 10 kV;

- The impedance measurement loop “phase-zero” (current single-phase short circuit) in installations with grounded neutral;

- Check breaker trip when the power supply system with grounded neutral;

- Test fuses with a voltage above 1000 V;

- Checking circuit breakers in electrical networks with voltage up to 1000 V to the triggering current;

- Inspection of protective devices.

Energy audits

Activities for conducting energy audits is governed by the Federal law dated 23.11.2009 No. 261-FZ “On energy saving and increasing energy efficiency, and on amendments to certain legislative acts of the Russian Federation”.

Energy audit is the collection and processing of information about the use of energy and water to:

- Obtaining reliable data on the amount of use of energy and water

- The compilation of energy balances

- Determine the energy efficiency potential of its increase

- Identify inefficiently used equipment and development of recommendations on optimization of operation modes

- Development and valuation of measures aimed at energy saving and increasing energy efficiency

- Development of energy efficiency programs

GAZMASHPROEKT is a member of NP SRO “Guild of energy Auditors”, the activities of the company fully complies with the requirements, norms and standards of the Russian legislation in the field of energy saving and energy efficiency.

According to the results of the energy survey, our clients receive:

- Energy performance certificates (fully meets the requirements of Order of Ministry of energy of Russia and the Federal law №261), registered in the Ministry of energy of the Russian Federation

- General description of the energy resources of the inspected object

- Description of methods of examination

- Graphs of flow and energy and water consumption

- Recommendations to reduce energy costs and water

- Calculation of the efficiency from the implementation of proposed recommendations

- The program of energy saving and increase of energy efficiency

Our service:

- Execution of works “turnkey”

- Qualified professionals

- Material-technical base

- Extensive experience in the field of energy saving and energy efficiency

- Optimal cost of services

- All our activities and its results fully comply with the law

- Individual approach

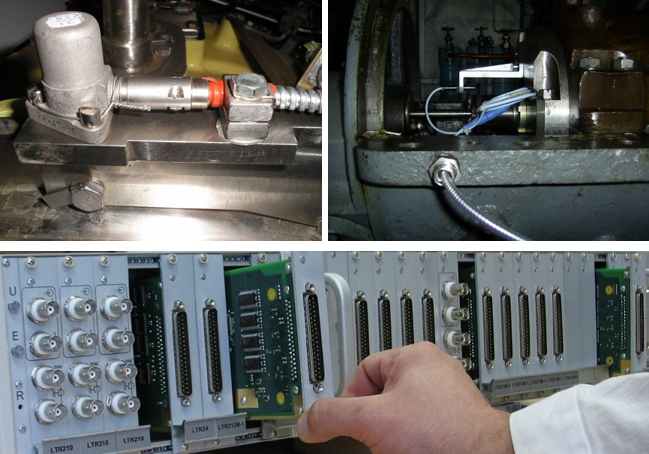

Development, design, installation and maintenance of stationary automated systems:

- vibration monitoring

- diagnostics of pump and compressor equipment

GAZMASHPROEKT is the winner of open tenders for the supply of stationary diagnostic systems “turnkey”, and providing services in the field of predictive maintenance conducted by PJSC “SIBUR holding”. In the framework of these projects, our company is equipped with systems of technological equipment of the following companies:

- Tobolsk-Neftekhim

- November GPK

- Yuzhno Balyksky GPP

- Gubkinskiy GPK

- SIBUR-Neftekhim

In the framework of the supply equipment are as follows:

- Equipment systems of vibration, vibromonitoring and diagnostics of dynamic equipment, including in hazardous areas. The whole range works on the principle of “turnkey” and includes cycles of design, installation and commissioning, commissioning, warranty and post-warranty service.

- Retrofitting existing systems with additional measurement channels and special programs to ensure the emergency protection of the equipment.

- Supply ZIP of components and systems in operation.

- Supply portable diagnostic equipment for diagnostic laboratories companies.)

In the framework of the maintenance of systems of vibration, vibromonitoring and diagnostics of technological equipment of enterprises of the following types of works:

– Work on a timely and periodic maintenance of the existing systems of vibration, vibromonitoring and diagnostics in order to maintain the required functional reliability, prevention of failures, prevent premature failure and maintain operational characteristics (parameters) of the system within established standards and ensuring constant readiness of equipment for use for its intended purpose.

– Carrying out of works on calibration of measuring vibration parameters. (Certificate of accreditation for conducting calibration services Registry No. 001242 Valid till 03 Nov 2015).

– Calibration of the sensors of absolute and relative vibration, and vibration measuring instruments and measuring systems.

All proposed equipment is included in the State register of measuring instruments for explosion-proof version obtained the GOST R Certificates and Permits for use of Federal Environmental, Industrial and Nuclear Supervision Service.

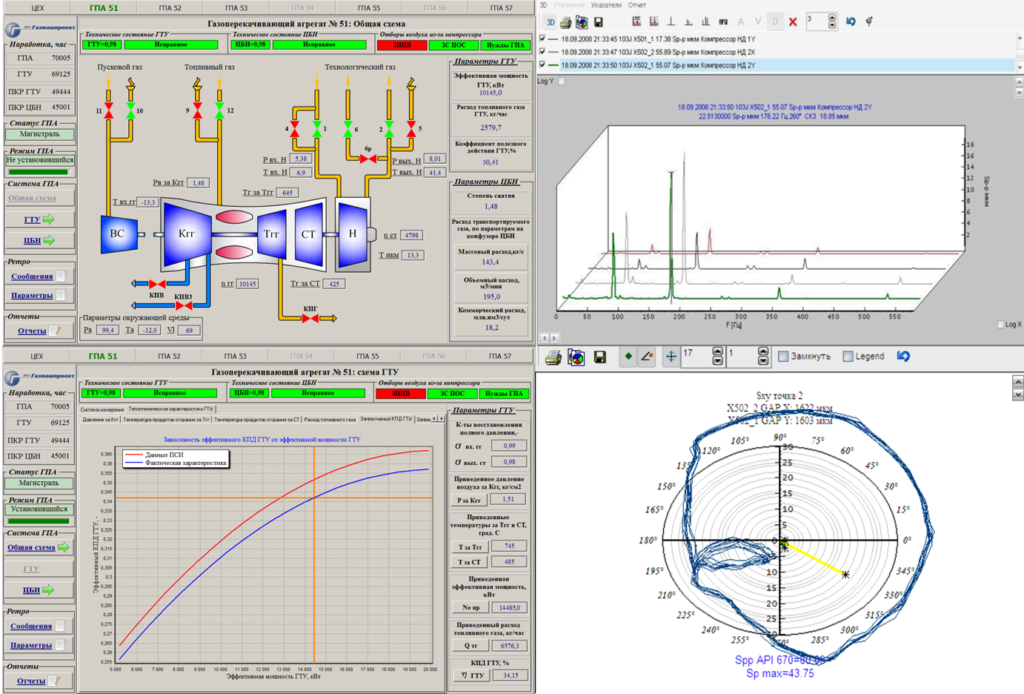

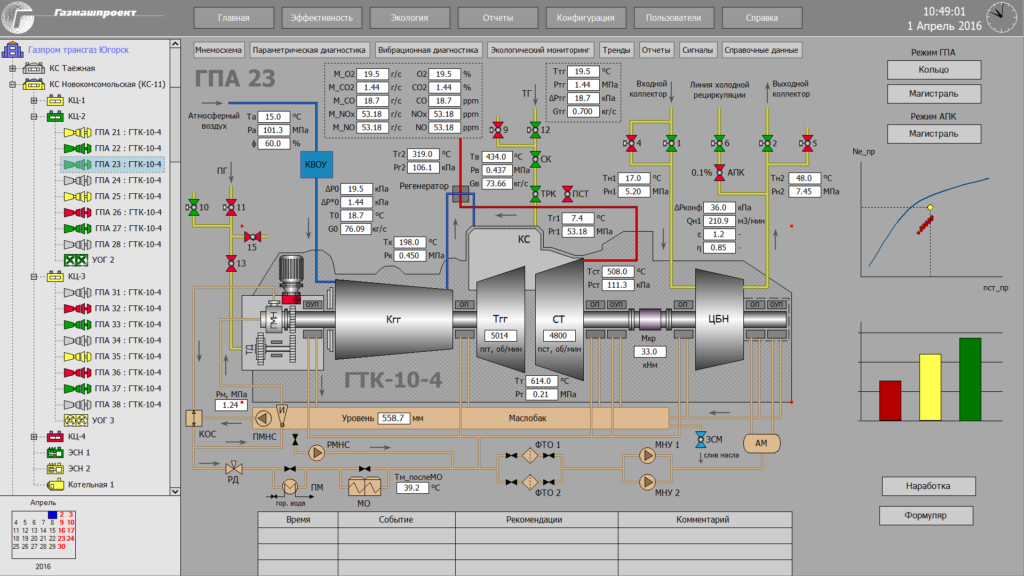

Development and design of automated information systems for industrial facilities

Automated information system –software system that monitors operating parameters of equipment and technological process on the basis of these control systems and telemechanics, as well as analysis of technical condition and efficiency of equipment using specialized expert algorithms. The basis of the modern automated information systems is software that contains unique algorithms for collecting, processing and analyzing data, an important feature is the use in the systems of high-precision measuring equipment, have a significant effect on the quality of the system’s functions.

Computerized diagnostic system for Turbomachinery (gas, oil and petrochemical industries):

- Subsystem parametric diagnostics of gas pumping units (GPA) gas turbine driven compressor units, gas turbine power plants;

- Subsystem vibration monitoring and diagnostics of turbo-compressor units (GPA) with gas turbine drive, compressor units, gas turbine, gas generators and electric motors;

- Modernization of existing systems of vibration protection with enhanced diagnostic functionality (software and hardware platform of domestic and foreign production).

Automated information system of energy and environmental monitoring of gas, oil and petrochemical industries:

- Subsystem performance monitoring of energy and technological equipment of compressor stations (GPA, AVO gas, gas turbine and gas piston power plants for own needs of boiler-houses);

- The subsystem of environmental monitoring of energy and technological equipment of compressor stations (GPA, AVO gas, gas turbine and gas piston power plants for own needs of boiler-houses).

Power equipment

To date, GAZMASHPROEKT performs work on capital and current repair of electrical equipment branches in Orenburg and Astrakhan.

The complex of works on repair of electrical equipment includes such operations as:

- installation and commissioning of switchboard equipment;

- overhaul and repair of backup power sources;

- capital repair of lightning protection;

- installation and commissioning of СTР (complete transformer substations);

- installation of lighting lines;

- overhaul of external and internal networks of power supply;

- maintenance of electrical equipment of ventilation systems;

- technical maintenance of fire security

Currently GAZMASHPROEKT shall maintain construction and Assembly works, monitors the deadlines and quality of work, develops schedules of manufacture of works, funding and regulates the movement of labor, ensures the supply of all necessary construction materials and equipment, strictly observe the safety conditions of construction works, health and the environment. Constant interaction with reliable partners allows us to perform work at different levels of complexity.

The aim of the work of specialists GAZMASHPROEKT is a high-quality performance of assigned tasks to ensure safe and durable operation of the equipment.

Modernization of industrial equipment

GAZMASHPROEKT has considerable experience in creating unique samples of equipment according to customer’s specifications and bring them to mass production. From design to the finished product.

The successful solution of this task contribute to the recruitment of highly qualified, experienced, technically competent staff in the project units, as well as its own production and technical base, the capacity of subsidiaries and long-established connections with adjacent industrial enterprises.

Most of the products, commercially available GAZMASHPROEKT and scientific-production enterprise NPO “Gaztehnomash”, began with prototypes manufactured to address the pressing challenges facing the subsidiaries of “Gazprom” jointly formulated the Technical reqest.

Company for 2005 and 2010 developed and implemented the following systems:

- CRP system pumps oil seals “oil-gas” for units of type GTK-10 OOO Gazprom transgaz Yugorsk”

- System CRP fans of air-condensing units BUTEK KS “Chaplygin”, OOO “Gazprom transgaz Moscow”

- Blocks the pressurization of the ventilation system of the compartments of GTK-25I with CRP KS “davydovskoe”, OOO “Gazprom transgaz Moscow”

- Control cabinets for oil purification systems of the type MAFO OOO Microcenter”

- Electrical cabinets of various modifications

In the framework of production and delivery, we offer the following products:

- Low-voltage complete devices

- The system is frequency-regulated electric drive

- Mobile gas heater for industrial premises GMP-500

- Ventilation and heating of industrial objects

- Nitrogen units stationary and mobile execution

Development and design of low-voltage devices of input, distribution and control of electric power up to 0.4 kV

Low-voltage complete device (NKY) is intended for reception and distribute electric power of three-phase alternating current with frequency 50 Hz and voltage 0.4 kV in the networks with dead-earthed or isolated neutral, the electric equipment control and protection against short-circuit currents and overloads.

NKY up to 0.4 kV different designs, including modular and extendable from fixed cells:

- Master control panels (SCHSU);

- Water-distribution device;

- Items and boxes;

- Flaps and boxes lighting control;

- TCU control, protection, alarm and control;

- Blocks and control panel asynchronous motors;

- Input units and distribution of electricity;

- Station control, protection and automation soft starters and frequency converters;

- The TCU input of electricity with the RRO;

- Panels of own needs of substations AC and DC;

- Main switchboards (MSB).